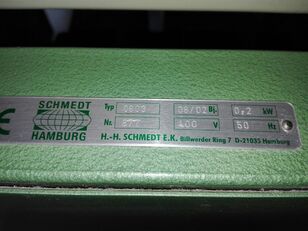

SAM coating flexo printing machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

2 coating stations

1 for primer (Gravure)

1 for Lackering (semiflexo), from the year 2014, ZERO Km machine

Gear in speed: 200 meters per minute (mpm)

Production speed: 150 meters per minute (depending on the coating and working condition)

Width of web: 620 mm min. 1250 mm max.

Width of guide roll: 1400mm

Applicable web: Tension range 60-600 N/m

Material: AL-Foil ( 20-50 micron)

Roll weight: 1,800 kg maximum

Unwind Diameter: 800 mm max.

Rewind Diameter: 800 mm max.

Steel core: Inner diameter Unwind: 6' air expansion shaft chucking design Rewind: 6' air expansion shaft chucking design

Thread speed: 5-20 mpm (user selectable)

Acceleration: 90 mpm / sec

Deceleration: 90 mpm / sec

Line stop: 20 mpm / sec

Emergency stop: 6 mpm / sec

Electric power: 380V x 50Hz x 3 phase

Aluminum foil: 20-50 microns

One Unwind

Two Web Guides: No.1 Web Guide, No.2 Web Guide

Three Infeeds: No.1 Infeed, No.2 Cooling Infeed, and No.3 Infeed

Two Coater hubs-No. 1 Coater and No.2 Coater— that can house any of two different Coater trolley units: A two-roll direct gravure coating unit with doctor. A semi-flexo three-roll offset gravure I-type coating unit

Two Dryers: No.1 Dryer with 2 dryer zones and No.2 Dryer with four dryer zones

Two Cooling Units: No.1 Cooling Unit with two cooling rollers and No.2

Cooling unit with three cooling roller and three tempering units for each roller.

Two Corona Treaters: No.1 Corona Treater and No.2 Corona Treater

One Rewind

Category: Coating

Farbe: 4